Embark on a comprehensive journey into the realm of small business inventory management ideas, where effective strategies and innovative solutions converge to empower your business. Delve into the intricacies of inventory tracking, forecasting, optimization, and more, unlocking the secrets to maximizing profits and minimizing waste.

As we navigate this essential aspect of business operations, we will uncover practical techniques and industry best practices, equipping you with the knowledge and tools to transform your inventory management into a competitive advantage. Get ready to optimize your inventory, streamline your operations, and propel your small business to new heights of success.

Inventory Management Strategies for Small Businesses: Small Business Inventory Management Ideas

Inventory management is crucial for small businesses to optimize operations, minimize waste, and maximize profits. Implementing effective strategies can help businesses maintain optimal inventory levels, reduce carrying costs, and enhance customer satisfaction.

Effective Inventory Management Techniques

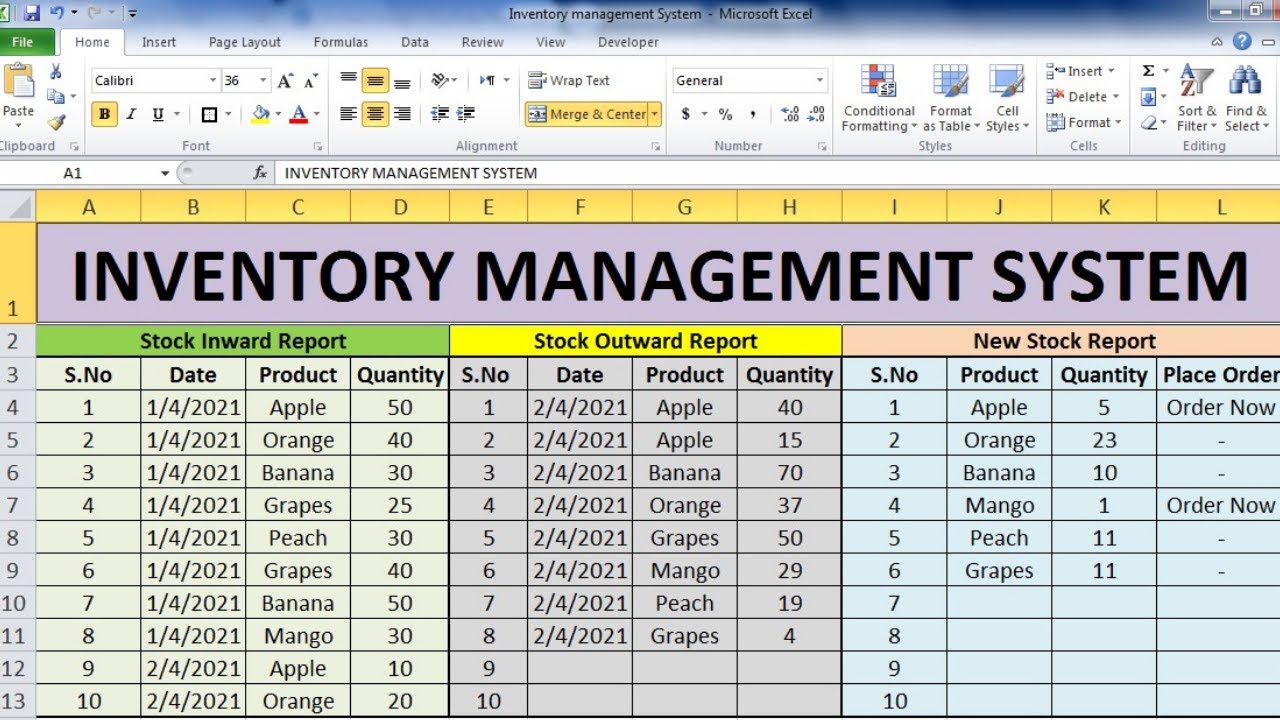

- Implement inventory tracking software:Using software streamlines inventory tracking, provides real-time visibility, and automates tasks like stock level updates and reordering.

- Conduct regular inventory audits:Physical audits ensure accuracy and identify discrepancies between actual and recorded inventory levels.

- Establish safety stock levels:Maintaining a buffer stock helps prevent stockouts and ensures smooth operations during demand fluctuations.

- Use the First-In, First-Out (FIFO) method:This method ensures that older inventory is sold first, minimizing the risk of obsolescence and spoilage.

- Monitor demand patterns:Analyzing historical sales data helps businesses forecast future demand and adjust inventory levels accordingly.

Benefits of Inventory Management Software

- Improved accuracy:Automates inventory tracking, reducing manual errors and ensuring data integrity.

- Real-time visibility:Provides instant access to inventory levels, enabling informed decision-making.

- Reduced labor costs:Automates tasks like stock counting and order processing, freeing up staff for other essential tasks.

- Enhanced customer satisfaction:Ensures product availability, reduces backorders, and improves delivery times.

li> Automated reordering:Triggers automatic reorders when stock reaches predefined levels, preventing stockouts.

Optimizing Inventory Levels

Optimizing inventory levels involves finding the right balance between carrying too much or too little inventory. Consider the following tips:

- Calculate inventory turnover:This metric measures how quickly inventory is sold and replaced, indicating inventory efficiency.

- Set target inventory levels:Determine the ideal inventory levels based on demand patterns, lead times, and safety stock requirements.

- Use inventory forecasting techniques:Forecast future demand using historical data and market trends to predict inventory needs.

- Monitor inventory levels regularly:Track inventory levels against target levels and adjust as needed to prevent overstocking or stockouts.

- Consider seasonal fluctuations:Adjust inventory levels to account for seasonal changes in demand.

Inventory Tracking and Control

Accurate and efficient inventory tracking is crucial for effective inventory management. This involves implementing robust methods to monitor stock levels, track item movements, and maintain up-to-date records.Inventory audits and cycle counting play a vital role in ensuring inventory accuracy. Audits involve a comprehensive physical count of all inventory items, while cycle counting focuses on counting specific sections or categories of inventory at regular intervals.

These processes help identify discrepancies, reduce shrinkage, and improve overall inventory visibility.

Barcode Scanners and RFID Tags

Barcode scanners and RFID (Radio Frequency Identification) tags are powerful tools for inventory control. Barcode scanners use optical technology to read barcodes printed on inventory items, enabling quick and accurate data capture. RFID tags, on the other hand, use radio waves to identify and track items, providing real-time visibility into inventory levels.

These technologies streamline inventory tracking processes, reduce manual errors, and enhance inventory accuracy.

Inventory Forecasting and Planning

Accurate inventory forecasting and planning are crucial for small businesses to optimize stock levels, minimize waste, and meet customer demand effectively. By leveraging historical data and market trends, businesses can develop robust strategies to ensure they have the right products in the right quantities at the right time.

Techniques for Forecasting Inventory Demand

- Time Series Analysis:Uses historical sales data to identify patterns and trends in demand over time.

- Causal Forecasting:Considers external factors that influence demand, such as seasonality, economic conditions, and marketing campaigns.

- Machine Learning:Employs algorithms to analyze complex data and predict future demand based on historical patterns and other relevant variables.

Safety Stock

Safety stock is a buffer inventory that protects businesses from unexpected fluctuations in demand or supply chain disruptions. Determining the optimal safety stock level involves balancing the costs of holding excess inventory against the risks of stockouts.

Planning Inventory Purchases

- Just-in-Time (JIT) Inventory:Orders inventory as needed, reducing storage costs but increasing the risk of stockouts.

- Economic Order Quantity (EOQ):Calculates the optimal order quantity to minimize total inventory costs, considering factors such as demand, ordering costs, and holding costs.

- Vendor Managed Inventory (VMI):Allows suppliers to manage inventory levels on behalf of the business, ensuring optimal stock levels and reducing the risk of stockouts.

Inventory Optimization for Space and Efficiency

Inventory optimization aims to reduce waste and maximize the utilization of available space and resources. For small businesses, this is crucial for controlling costs and improving operational efficiency.To optimize inventory for space and efficiency, consider the following principles:

Vertical Storage

Utilize vertical space by installing shelves, racks, and mezzanines to increase storage capacity.

High-Density Storage

Employ compact storage systems like pallet racks, drive-in racks, or automated storage and retrieval systems (ASRS) to maximize space utilization.

Efficient Layout

Design a logical inventory layout that minimizes travel distances and facilitates picking and packing.

FIFO Management

Implement a first-in, first-out (FIFO) inventory system to ensure that older inventory is used first, preventing spoilage or obsolescence.

Regular Inventory Audits

Conduct regular inventory audits to identify and remove obsolete or slow-moving items, freeing up valuable space.

Maximizing Storage Space

- Utilize vertical space with shelves, racks, and mezzanines.

- Employ high-density storage systems like pallet racks and drive-in racks.

- Design a logical inventory layout that minimizes travel distances.

- Implement a FIFO inventory system to ensure that older inventory is used first.

- Conduct regular inventory audits to identify and remove obsolete or slow-moving items.

Minimizing Handling Costs

- Utilize ergonomic equipment like forklifts and pallet jacks to reduce manual labor.

- Implement automated storage and retrieval systems (ASRS) to minimize handling costs.

- Train employees on proper inventory handling techniques to prevent damage and waste.

- Use inventory management software to optimize picking and packing processes.

- Implement a cross-docking system to eliminate unnecessary storage and handling.

Organizing Inventory for Efficiency

- Categorize and group similar items together to facilitate picking and packing.

- Use color-coded labels or tags to identify different inventory categories.

- Implement a zone-based inventory system to divide the warehouse into specific areas.

- Use inventory management software to track inventory levels and optimize picking routes.

- Regularly review and adjust inventory organization to improve efficiency.

Inventory Management for E-commerce Businesses

E-commerce businesses face unique inventory management challenges due to the absence of physical storefronts and the need for efficient online order fulfillment. Effective inventory management is crucial for maintaining customer satisfaction, optimizing storage space, and minimizing losses.

Managing Inventory Across Multiple Channels and Warehouses

E-commerce businesses often sell products through multiple channels, such as their own website, marketplaces like Amazon, and social media platforms. Additionally, they may have multiple warehouses located in different regions to facilitate faster delivery. Managing inventory across these channels and warehouses can be complex, requiring real-time tracking and coordination.

- Centralized Inventory Management System:Implement a central system that provides a real-time view of inventory levels across all channels and warehouses.

- Automated Inventory Allocation:Use software to automatically allocate inventory to different channels based on demand and availability.

- Cross-Docking:Establish a cross-docking facility where incoming goods are directly shipped to customers without being stored in a warehouse.

Optimizing Inventory for Fast and Accurate Order Fulfillment

Fast and accurate order fulfillment is essential for customer satisfaction and reducing shipping costs. E-commerce businesses must optimize their inventory to ensure that the right products are available in the right quantities at the right time.

- Safety Stock:Maintain a safety stock level to buffer against unexpected demand fluctuations and prevent stockouts.

- ABC Analysis:Classify inventory items based on their value and demand to prioritize inventory management efforts.

- Just-in-Time Inventory:Adopt a just-in-time inventory approach to minimize storage costs and improve inventory turnover.

- Efficient Warehouse Layout:Design the warehouse layout for efficient picking and packing operations.

Inventory Management for Service Businesses

Inventory management plays a critical role in the success of service businesses, ensuring the efficient and timely delivery of services to customers. It involves tracking and managing materials, supplies, and equipment necessary for service operations.

Effective inventory management for service businesses involves:

Tracking and Managing Inventory

- Establishing a comprehensive inventory system:This involves creating a system to track inventory levels, including materials, supplies, and equipment.

- Regular inventory audits:Conducting regular audits helps ensure accuracy and prevents overstocking or understocking.

- Implementing a first-in, first-out (FIFO) system:This method ensures that older inventory is used first, preventing spoilage or obsolescence.

Optimizing Inventory Levels

- Analyzing historical usage data:Examining past inventory usage patterns can help businesses forecast future demand and set optimal inventory levels.

- Establishing safety stock levels:Maintaining a buffer stock helps prevent stockouts and ensures uninterrupted service delivery.

- Utilizing inventory management software:These tools can automate inventory tracking, generate reports, and provide insights for better decision-making.

Inventory Management Case Studies

Small businesses that effectively manage their inventory experience improved profitability, enhanced customer satisfaction, and streamlined operations. Here are some notable case studies:

Case Study of a Manufacturing Company

- Challenge:A manufacturing company struggled with excessive inventory levels, leading to high storage costs and obsolete stock.

- Solution:Implemented an inventory management system that provided real-time visibility into inventory levels and demand patterns. This allowed them to optimize production schedules, reduce excess inventory, and improve inventory turnover.

- Results:Reduced inventory levels by 25%, lowered storage costs by 15%, and increased inventory turnover by 20%.

Case Study of a Retail Store

- Challenge:A retail store faced stockouts and overstocking due to inaccurate inventory tracking.

- Solution:Introduced a mobile inventory management app that enabled real-time inventory updates and automated stock replenishment. This improved inventory accuracy, reduced stockouts, and optimized inventory levels.

- Results:Increased sales by 10% through reduced stockouts, lowered inventory carrying costs by 12%, and improved customer satisfaction.

Case Study of an E-commerce Business

- Challenge:An e-commerce business experienced delays in order fulfillment due to inefficient inventory management.

- Solution:Integrated an inventory management platform with their e-commerce website, enabling automated inventory updates and order fulfillment. This streamlined the order processing and shipping process.

- Results:Reduced order fulfillment time by 50%, improved customer satisfaction, and increased repeat purchases.

Best Practices for Inventory Management

Inventory management is crucial for small businesses to optimize operations, minimize costs, and enhance customer satisfaction. Implementing best practices in inventory management can lead to significant improvements in efficiency, profitability, and overall business performance.

Key Best Practices

1. Establish Clear Inventory Policies:Define clear policies for inventory levels, reordering points, and stock replenishment to ensure consistency and avoid overstocking or understocking.

2. Implement Inventory Tracking Systems:Utilize inventory tracking software or manual systems to monitor inventory levels, track stock movements, and generate accurate reports.

3. Optimize Inventory Levels:Determine optimal inventory levels based on demand patterns, lead times, and safety stock requirements to minimize holding costs and prevent stockouts.

4. Conduct Regular Inventory Audits:Regularly conduct physical inventory audits to verify inventory accuracy, identify discrepancies, and improve inventory management processes.

5. Utilize Just-in-Time (JIT) Inventory:Implement JIT inventory practices to reduce inventory holding costs by ordering inventory only when needed, based on customer demand.

6. Manage Inventory Turnover:Track inventory turnover rates to identify slow-moving items and optimize inventory levels accordingly, reducing the risk of obsolete inventory.

7. Foster Collaboration with Suppliers:Establish strong relationships with suppliers to ensure timely delivery, negotiate favorable terms, and access to critical inventory items.

8. Utilize Technology for Inventory Management:Leverage inventory management software, mobile apps, and automation tools to streamline processes, improve accuracy, and enhance decision-making.

Benefits of Best Practices

Adopting best practices in inventory management can yield numerous benefits for small businesses:

– Reduced inventory costs – Improved customer service levels – Increased profitability – Enhanced operational efficiency – Improved inventory accuracy

Challenges of Best Practices, Small business inventory management ideas

While implementing best practices can be transformative, there are also challenges to consider:

– Time and Effort:Implementing and maintaining effective inventory management practices can be time-consuming and resource-intensive.

– Cost of Technology:Investing in inventory management software or other technologies can represent a significant expense for small businesses.

– Resistance to Change:Employees may resist changes to established inventory management processes, requiring effective communication and training.

– Lack of Expertise:Small businesses may lack the necessary expertise in inventory management, making it difficult to implement and optimize best practices.

Conclusion

In the ever-evolving landscape of small businesses, effective inventory management stands as a cornerstone of success. By embracing the ideas and strategies Artikeld in this comprehensive guide, you have embarked on a path of optimization and efficiency. Remember, inventory management is not merely a task but an art form, a delicate balance between meeting customer demand and minimizing waste.

As you continue to refine your practices, stay abreast of industry trends and technological advancements to maintain a competitive edge. With dedication and a commitment to excellence, you will unlock the full potential of your inventory, transforming it into a driving force for growth and profitability.

Frequently Asked Questions

What are the key benefits of implementing effective inventory management strategies?

Effective inventory management strategies can significantly reduce waste, optimize storage space, improve order fulfillment accuracy, enhance customer satisfaction, and ultimately increase profitability.

How can I accurately track and control my inventory levels?

Utilize a combination of methods such as regular inventory audits, cycle counting, barcode scanners, and RFID tags to ensure accurate and efficient inventory tracking and control.

What techniques can I use to forecast inventory demand effectively?

Leverage historical data, market trends, and industry insights to develop accurate inventory forecasts. Determine optimal safety stock levels to avoid stockouts and overstocking.