Inventory management system business value is a crucial aspect of modern business operations, enabling companies to streamline their inventory processes, optimize stock levels, and drive profitability. This comprehensive guide delves into the benefits, challenges, and best practices associated with implementing an inventory management system, empowering businesses to unlock the full potential of their inventory.

With the increasing complexity of supply chains and the growing demand for efficient inventory management, businesses are turning to inventory management systems to gain a competitive edge. These systems offer a range of features that automate inventory tracking, provide real-time visibility, and facilitate data-driven decision-making.

Inventory Management System Overview

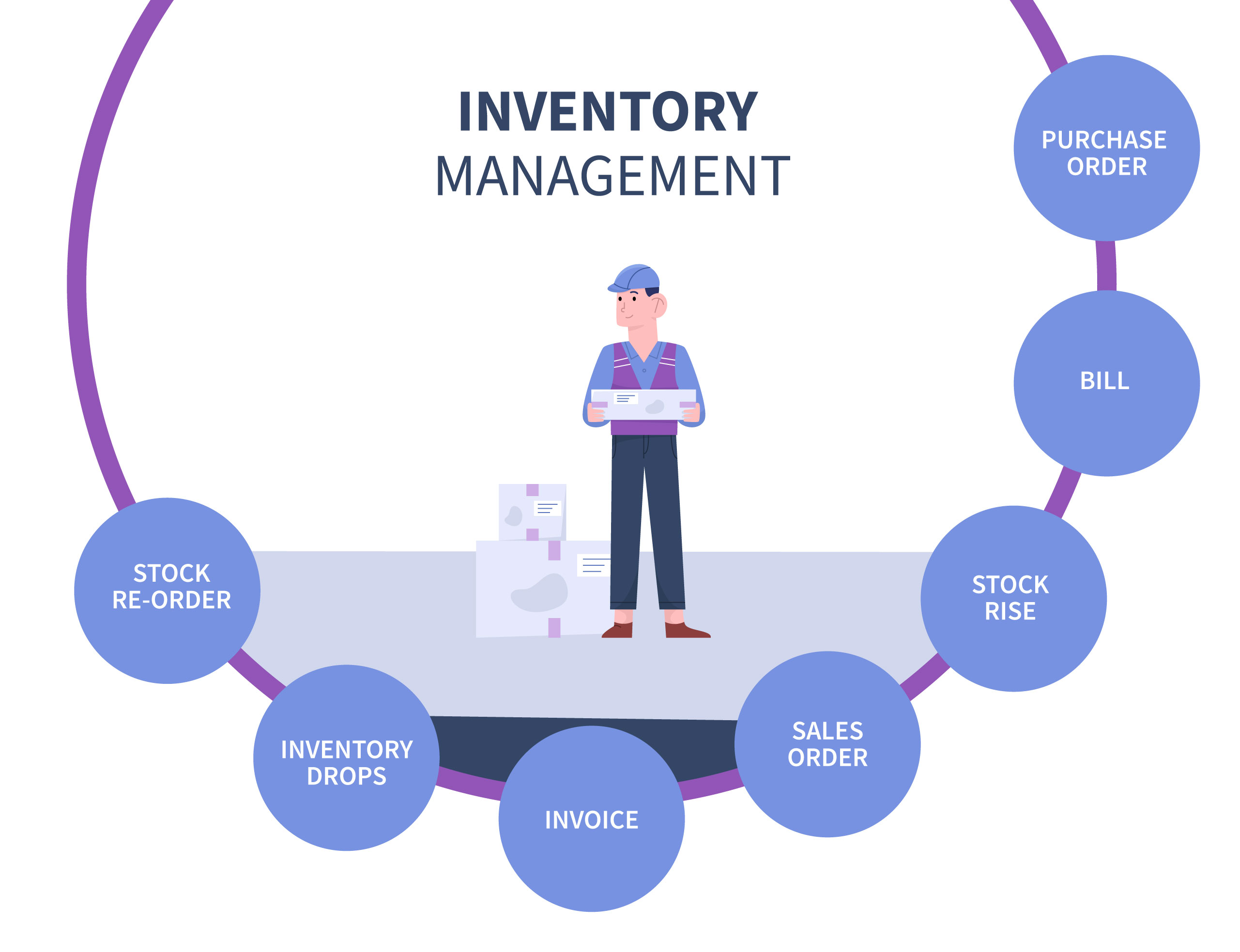

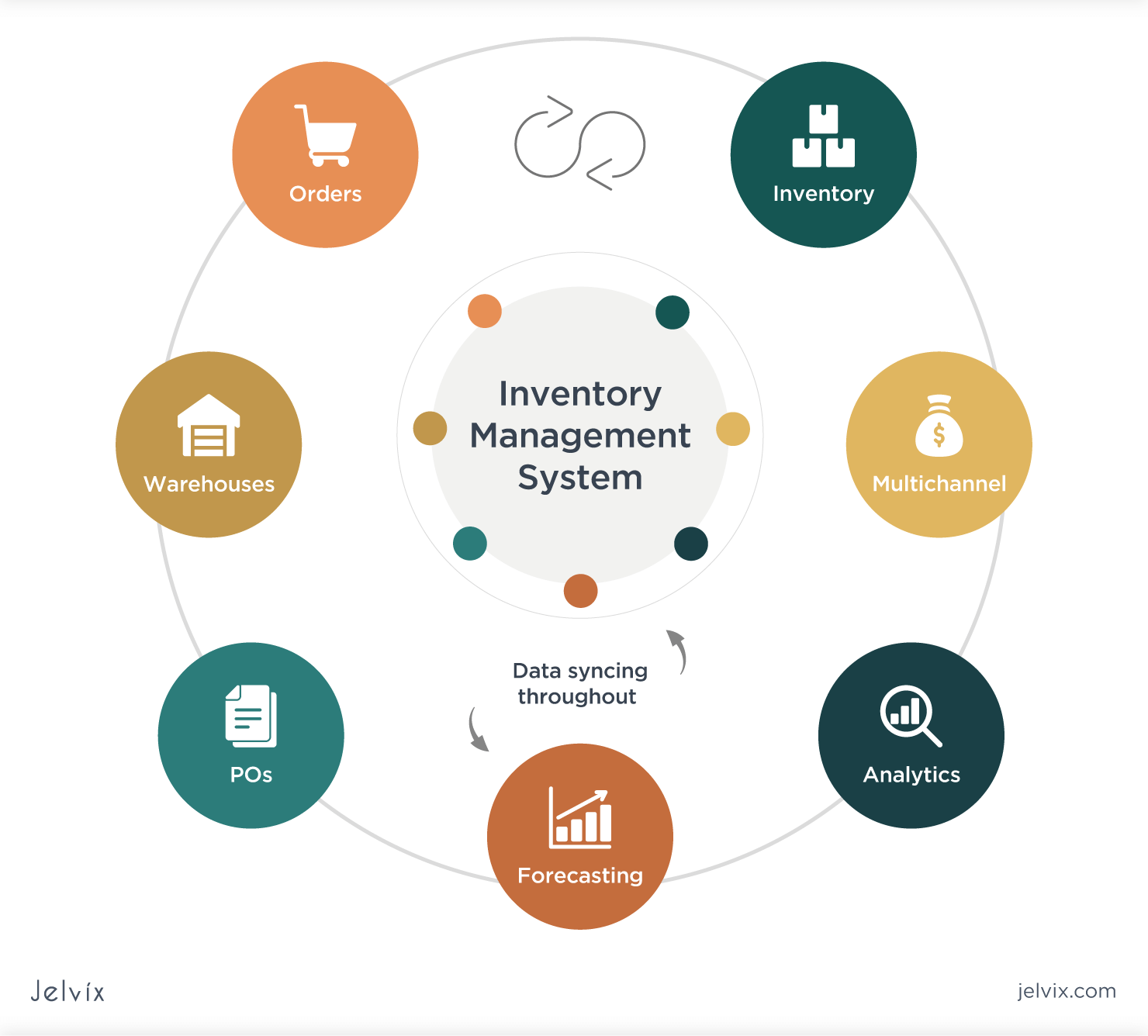

An inventory management system is a software application that helps businesses track and manage their inventory. It can be used to track the quantity of items in stock, the location of items, and the cost of items. Inventory management systems can also be used to generate reports on inventory levels, track inventory trends, and forecast future inventory needs.

There are many benefits to implementing an inventory management system. Some of the benefits include:

- Reduced inventory costs: An inventory management system can help businesses reduce their inventory costs by optimizing inventory levels. By tracking inventory levels, businesses can avoid overstocking and understocking, which can lead to lost sales and increased costs.

- Improved customer service: An inventory management system can help businesses improve their customer service by providing accurate and up-to-date information on inventory levels. This information can help businesses fulfill orders more quickly and efficiently, which can lead to increased customer satisfaction.

- Increased efficiency: An inventory management system can help businesses increase their efficiency by automating inventory management tasks. This can free up employees to focus on other tasks, such as sales and marketing.

Types of Inventory Management Systems: Inventory Management System Business Value

Inventory management systems (IMS) can be classified into various types based on their functionality, complexity, and the size of the organization they are designed for. The different types of IMS available include:

Perpetual Inventory System

- Tracks inventory levels in real-time as transactions occur.

- Provides up-to-date information on stock availability and can be integrated with other systems like POS and accounting.

- Examples: QuickBooks, NetSuite, SAP S/4HANA

Periodic Inventory System

- Counts inventory at specific intervals (e.g., monthly or quarterly).

- Less accurate than perpetual systems, but simpler to implement and maintain.

- Examples: Manual inventory tracking using spreadsheets or physical count sheets

First-In, First-Out (FIFO) System

- Assumes that the oldest inventory is sold first.

- Can result in higher cost of goods sold (COGS) during periods of inflation.

- Examples: Grocery stores, restaurants

Last-In, First-Out (LIFO) System

- Assumes that the newest inventory is sold first.

- Can result in lower COGS during periods of inflation.

- Examples: Oil and gas companies, mining companies

Just-In-Time (JIT) System

- Aims to minimize inventory levels by ordering only what is needed, when it is needed.

- Requires close coordination with suppliers and can be challenging to implement.

- Examples: Toyota, Dell

Key Features of an Inventory Management System

Inventory management systems offer various features that can significantly enhance inventory management processes. These features automate tasks, provide real-time visibility, and optimize inventory levels, leading to improved efficiency, cost reduction, and increased profitability.

Centralized Inventory Management

- Centralized systems provide a single platform for managing inventory across multiple locations and channels.

- They eliminate the need for manual record-keeping and data entry, reducing errors and improving accuracy.

Real-Time Inventory Tracking

- Real-time tracking allows businesses to monitor inventory levels in real-time, ensuring accurate and up-to-date information.

- This enables timely replenishment and prevents overstocking or stockouts.

Automated Inventory Replenishment

- Automated replenishment systems use algorithms to monitor inventory levels and trigger purchase orders when stock falls below predetermined thresholds.

- This ensures optimal inventory levels, reduces the risk of stockouts, and optimizes cash flow.

Demand Forecasting

- Demand forecasting tools analyze historical data and market trends to predict future demand.

- This helps businesses plan production and inventory levels accordingly, minimizing the risk of overstocking or understocking.

Inventory Optimization

- Inventory optimization algorithms determine the optimal inventory levels for each item, considering factors such as demand, lead times, and storage costs.

- This helps businesses reduce inventory carrying costs while ensuring adequate stock levels to meet customer demand.

Reporting and Analytics

- Inventory management systems provide comprehensive reports and analytics that offer insights into inventory performance, trends, and areas for improvement.

- This data enables businesses to make informed decisions and identify opportunities to optimize their inventory management processes.

Benefits of Implementing an Inventory Management System

Inventory management systems offer numerous benefits that can streamline operations and enhance business performance. By implementing an inventory management system, businesses can:

- Reduce costs:An inventory management system can help businesses reduce costs by optimizing inventory levels, minimizing waste, and improving efficiency.

- Improve customer service:By providing real-time visibility into inventory levels, an inventory management system can help businesses avoid stockouts and meet customer demand more effectively.

- Increase sales:An inventory management system can help businesses increase sales by ensuring that products are available when customers need them.

- Improve profitability:By reducing costs, improving customer service, and increasing sales, an inventory management system can help businesses improve profitability.

Examples of Benefits

Numerous businesses have benefited from implementing an inventory management system. For example, a large retailer implemented an inventory management system and was able to reduce its inventory by 20%, resulting in significant cost savings. A small manufacturer implemented an inventory management system and was able to increase its sales by 15% by improving its customer service.

Challenges of Implementing an Inventory Management System

Implementing an inventory management system can bring significant benefits to a business, but it also comes with its own set of challenges. These challenges can range from technical issues to organizational resistance, and it is important to be aware of them before embarking on an implementation project.

Data Accuracy and Integration

One of the biggest challenges of implementing an inventory management system is ensuring that the data is accurate and integrated with other business systems. This can be a difficult task, especially if the business has a large number of SKUs or if the data is spread across multiple systems.

Cost

Implementing an inventory management system can be a significant investment, both in terms of software and hardware. In addition, there are ongoing costs associated with maintaining the system and keeping it up-to-date.

Training

Employees need to be trained on how to use the new inventory management system, which can take time and resources. This can be especially challenging if the system is complex or if the employees are not familiar with technology.

Resistance to Change, Inventory management system business value

Some employees may be resistant to change, and this can make it difficult to implement a new inventory management system. This resistance can be overcome by communicating the benefits of the system and by providing training and support to employees.

Tips for Overcoming Challenges

There are a number of things that businesses can do to overcome the challenges of implementing an inventory management system. These include:

- Planning carefully and involving all stakeholders in the implementation process

- Choosing a system that is appropriate for the business’s needs and budget

- Investing in training and support for employees

- Communicating the benefits of the system to employees and getting their buy-in

- Monitoring the system’s performance and making adjustments as needed

By following these tips, businesses can increase the chances of a successful inventory management system implementation.

Best Practices for Inventory Management

Effective inventory management is crucial for businesses to optimize their operations, minimize costs, and enhance customer satisfaction. Here are some best practices to help businesses manage their inventory effectively:

Centralized Inventory Management

Maintaining a centralized inventory system provides a comprehensive view of inventory levels across multiple locations, enabling businesses to track stock levels, identify discrepancies, and make informed decisions.

Regular Inventory Audits

Regular inventory audits help businesses identify and rectify discrepancies between physical inventory and system records. This ensures accurate inventory levels and prevents overstocking or stockouts.

Demand Forecasting

Accurate demand forecasting enables businesses to anticipate future demand and adjust inventory levels accordingly. This helps avoid overstocking during slow periods and stockouts during peak demand.

Just-in-Time (JIT) Inventory

The JIT inventory management approach aims to minimize inventory levels by receiving goods only when they are needed for production or sale. This reduces storage costs and the risk of obsolescence.

Safety Stock Management

Maintaining an appropriate level of safety stock helps businesses buffer against unexpected demand fluctuations or supply chain disruptions, ensuring uninterrupted operations.

Vendor Management

Effective vendor management is crucial for ensuring timely delivery of goods and maintaining quality standards. Businesses should establish clear communication channels with vendors and monitor their performance regularly.

Technology Utilization

Leveraging inventory management software and technologies can automate processes, improve data accuracy, and provide real-time visibility into inventory levels. This enables businesses to make data-driven decisions and optimize inventory management.

Continuous Improvement

Regularly reviewing and refining inventory management processes helps businesses identify areas for improvement and implement best practices. This ensures that inventory management remains efficient and aligned with business objectives.

Emerging Trends in Inventory Management

Inventory management is constantly evolving, with new trends emerging all the time. These trends are shaping the future of inventory management, making it more efficient, accurate, and cost-effective.

Artificial Intelligence (AI)

AI is rapidly becoming a key player in inventory management. AI-powered systems can automate tasks, such as forecasting demand, optimizing inventory levels, and managing supplier relationships. This can free up valuable time for human workers, allowing them to focus on more strategic tasks.

Internet of Things (IoT)

The IoT is another emerging trend that is having a major impact on inventory management. IoT devices can be used to track inventory in real time, providing businesses with a complete and up-to-date view of their inventory levels. This can help businesses avoid stockouts and overstocking, and can also improve efficiency and accuracy.

Cloud Computing

Cloud computing is another important trend in inventory management. Cloud-based inventory management systems can be accessed from anywhere, making it easy for businesses to manage their inventory from multiple locations. Cloud-based systems can also be scaled up or down to meet the changing needs of a business, making them a cost-effective option for businesses of all sizes.

Blockchain

Blockchain is a distributed ledger technology that is being used to improve the security and transparency of inventory management systems. Blockchain can help to prevent fraud and theft, and can also improve the efficiency of inventory management processes.These are just a few of the emerging trends that are shaping the future of inventory management.

As these trends continue to develop, businesses will be able to improve their inventory management processes, reduce costs, and improve customer service.

Case Studies of Successful Inventory Management

Inventory management systems have proven to be instrumental in transforming business operations, leading to significant gains in efficiency, cost reduction, and customer satisfaction. Numerous businesses across various industries have realized substantial benefits from implementing these systems.

Case Study: XYZ Retail Company

XYZ Retail Company, a leading fashion retailer, faced challenges with managing inventory levels across its multiple stores. The company implemented an inventory management system that provided real-time visibility into stock levels, optimized replenishment, and reduced overstocking and stockouts. As a result, XYZ Retail Company experienced a 15% increase in sales and a 10% reduction in inventory carrying costs.

Case Study: ABC Manufacturing Company

ABC Manufacturing Company, a manufacturer of industrial equipment, struggled with production delays due to inaccurate inventory records. The company implemented an inventory management system that integrated with its production planning software. This integration enabled the system to automatically trigger production orders based on real-time inventory levels.

Consequently, ABC Manufacturing Company reduced production delays by 20% and improved customer satisfaction.

Return on Investment (ROI) of an Inventory Management System

The return on investment (ROI) of an inventory management system is a measure of the financial benefits that a business can expect to achieve from implementing the system. ROI can be calculated by comparing the costs of implementing the system to the benefits that it generates.

For example, a business may see a decrease in inventory costs, an increase in sales, or an improvement in customer satisfaction as a result of implementing an inventory management system.

The following are some examples of how businesses have achieved a positive ROI from implementing an inventory management system:

- A manufacturing company reduced its inventory costs by 15% by implementing an inventory management system that helped it to optimize its inventory levels.

- A retail store increased its sales by 10% by implementing an inventory management system that helped it to improve its customer service.

- A healthcare provider improved its patient satisfaction by 5% by implementing an inventory management system that helped it to improve its medication management.

Future of Inventory Management

The future of inventory management is bright, with technology continuing to play a major role in shaping the way businesses manage their inventory. Advances in artificial intelligence (AI), machine learning (ML), and the Internet of Things (IoT) are expected to revolutionize the way businesses track, manage, and optimize their inventory levels.

One of the most significant trends in inventory management is the increasing use of AI and ML. These technologies can be used to automate many of the tasks associated with inventory management, such as forecasting demand, optimizing inventory levels, and managing supply chains.

This can lead to significant cost savings and improved efficiency for businesses.

Role of IoT in Inventory Management

The IoT is also playing a major role in the future of inventory management. IoT devices can be used to track the location and status of inventory items in real time. This information can be used to improve inventory accuracy, reduce shrinkage, and optimize supply chain management.

Predictive Analytics and Inventory Management

Predictive analytics is another important trend in inventory management. Predictive analytics can be used to forecast demand, identify trends, and predict future inventory needs. This information can help businesses make better decisions about inventory levels, production schedules, and supply chain management.

Overall, the future of inventory management is bright. Technology is continuing to make it easier for businesses to track, manage, and optimize their inventory levels. This is leading to significant cost savings, improved efficiency, and better customer service.

End of Discussion

In conclusion, inventory management system business value is undeniable. By implementing an effective inventory management system, businesses can streamline their operations, reduce costs, improve customer satisfaction, and gain a strategic advantage in the marketplace. As technology continues to evolve, inventory management systems will become even more sophisticated, offering businesses new opportunities to optimize their inventory and drive growth.

FAQ Resource

What are the key benefits of implementing an inventory management system?

Inventory management systems offer numerous benefits, including reduced inventory costs, improved customer satisfaction, increased operational efficiency, and enhanced data visibility.

What are the common challenges associated with implementing an inventory management system?

Common challenges include data accuracy, system integration, and employee training. However, these challenges can be overcome with proper planning and implementation.

How can businesses calculate the ROI of an inventory management system?

Businesses can calculate the ROI by comparing the cost of implementing the system to the benefits it generates, such as reduced inventory costs and increased sales.