In the realm of inventory management, understanding the inventory business product structure is paramount. It serves as the foundation for organizing and managing a company’s inventory, optimizing operations, and maximizing profitability. This comprehensive guide delves into the concept, types, design, implementation, maintenance, and successful case studies of inventory business product structures, empowering businesses to harness its transformative power.

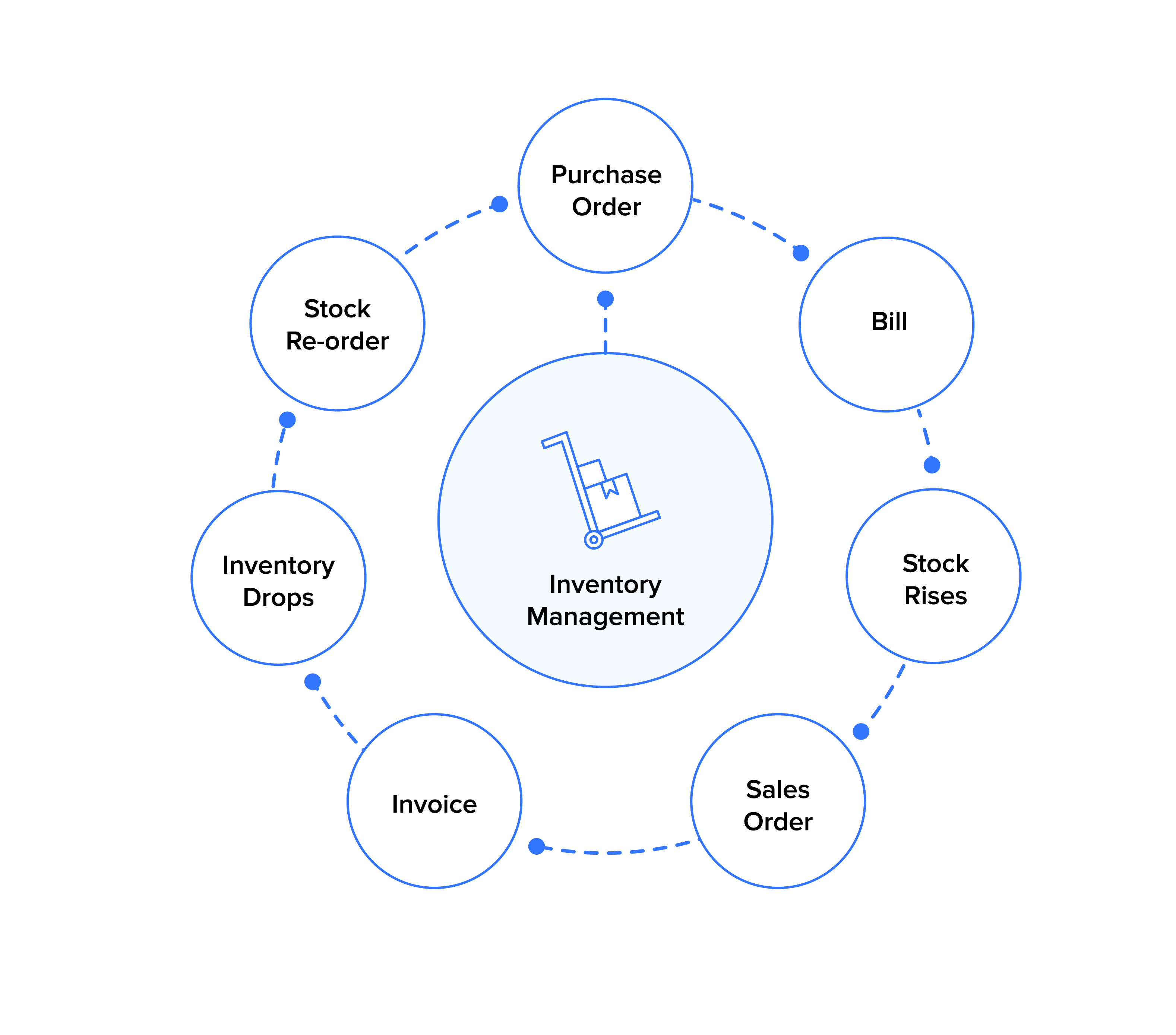

Inventory business product structure provides a systematic approach to categorizing and organizing inventory items based on their relationships, characteristics, and usage patterns. By establishing a well-defined structure, businesses gain enhanced visibility into their inventory, enabling them to make informed decisions, reduce waste, and improve overall efficiency.

Inventory Business Product Structure Overview

An inventory business product structure defines how products are organized and classified within an inventory system. It provides a hierarchical framework that helps businesses manage and track their inventory effectively.

Different types of inventory business product structures include:

- Single-level structure:All products are listed at the same level without any subcategories.

- Multi-level structure:Products are organized into categories and subcategories, creating a hierarchical structure.

- Location-based structure:Products are organized based on their physical location within the warehouse or inventory system.

Using an inventory business product structure offers several benefits, including improved inventory organization, enhanced inventory tracking, optimized inventory management, and increased efficiency in inventory operations.

Types of Inventory Business Product Structures

Inventory business product structures categorize the organization and management of inventory items based on their relationships and dependencies. Different types of structures are used to suit the specific needs and complexities of various businesses.

Single-Level Product Structure

A single-level product structure is the simplest and most straightforward type of structure. It represents a one-to-one relationship between parent products and their components. Each parent product has a unique set of components that are directly associated with it, and there are no sub-assemblies or intermediate levels.

Example:A bicycle manufacturer using a single-level structure would have parent products like “Bicycle” and “Helmet,” with components like “Frame,” “Wheels,” and “Brakes” directly linked to the parent product.

Advantages:

- Simplicity and ease of management

- Reduced complexity and fewer dependencies

Disadvantages:

- Limited flexibility for complex products

- Difficulty in handling product variants or configurations

Multi-Level Product Structure

A multi-level product structure introduces hierarchy and relationships between products. It allows for parent products to have sub-assemblies, which are in turn composed of their own components. This structure provides greater flexibility and scalability for complex products.

Example:A computer manufacturer using a multi-level structure would have a parent product like “Computer,” with sub-assemblies like “Motherboard,” “Processor,” and “Graphics Card,” each with its own set of components.

Advantages:

- Increased flexibility and scalability

- Improved visibility and control over complex products

- Simplified management of product variants and configurations

Disadvantages:

- Increased complexity and dependencies

- Potential for data inconsistencies if not managed properly

Matrix Product Structure

A matrix product structure combines elements of both single-level and multi-level structures. It allows for multiple levels of hierarchy while also introducing a matrix-like relationship between products and components. This structure is used when products have multiple options and configurations.

Example:A clothing manufacturer using a matrix structure would have a parent product like “T-Shirt,” with attributes like “Color,” “Size,” and “Fabric.” Each combination of attributes would create a unique product variant.

Advantages:

- High flexibility and customization

- Efficient management of product variants

Disadvantages:

- Increased complexity and data management challenges

- Potential for inventory inaccuracies if not managed carefully

Inventory Business Product Structure Implementation

Implementing an inventory business product structure involves establishing a logical and organized framework for classifying, categorizing, and managing inventory items. It requires careful planning and execution to ensure the structure aligns with the business’s operational needs and goals.

Transitioning Between Structures

Transitioning from one type of inventory business product structure to another requires a systematic approach to avoid disruptions and data loss. It’s crucial to map the existing structure to the new one, ensuring a seamless transfer of data and maintaining the integrity of inventory records.

Communication and training are essential to inform stakeholders about the changes and ensure smooth adoption.

Challenges and Risks, Inventory business product structure

Implementing an inventory business product structure can present challenges and risks, including:

Data migration

Moving data from one structure to another can be complex and time-consuming, requiring careful planning and data validation.

Disruptions to operations

Implementing a new structure can temporarily disrupt inventory operations, affecting order fulfillment and customer satisfaction.

Training and adoption

Employees may need training to understand the new structure and adopt new processes, which can impact productivity.

Cost and resources

Implementing a new inventory business product structure can involve significant costs and require additional resources, such as software or consulting services.

Inventory Business Product Structure Case Studies

Several businesses have successfully implemented inventory business product structures to enhance their operations and achieve significant benefits. Let’s explore some case studies to understand the challenges, successes, and key factors contributing to their success.

Case Study: ABC Manufacturing

- Challenges:Managing a complex product portfolio with varying lead times and demand patterns.

- Successes:Implemented an inventory business product structure that categorized products based on their turnover rate and demand variability. This enabled them to optimize inventory levels, reduce stockouts, and improve customer service.

- Key Factors:Clear understanding of product demand patterns, collaboration between sales, operations, and finance teams, and robust inventory management software.

Case Study: XYZ Retail

- Challenges:Optimizing inventory levels across multiple retail locations with varying sales volumes and customer preferences.

- Successes:Established an inventory business product structure that segmented products based on their seasonality, demand predictability, and profit margins. This allowed them to allocate inventory effectively, reduce markdowns, and increase sales.

- Key Factors:Data-driven analysis of sales patterns, centralized inventory management system, and strong vendor relationships.

Case Study: PQR Distribution

- Challenges:Managing a large and diverse inventory of perishable goods with short shelf lives and strict quality control requirements.

- Successes:Implemented an inventory business product structure that classified products based on their perishability, storage requirements, and traceability. This enabled them to minimize spoilage, ensure product quality, and comply with regulatory standards.

- Key Factors:Automated inventory tracking system, collaboration with suppliers and logistics providers, and rigorous quality control processes.

Last Word

Mastering inventory business product structure is a journey that requires careful planning, implementation, and ongoing maintenance. By embracing the principles Artikeld in this guide, businesses can unlock the full potential of their inventory, streamline operations, and gain a competitive edge in today’s dynamic market landscape.

User Queries: Inventory Business Product Structure

What are the key benefits of using an inventory business product structure?

Improved inventory visibility, reduced waste, enhanced decision-making, optimized operations, and increased profitability.

What are the different types of inventory business product structures?

Single-level, multi-level, and matrix structures, each with its own advantages and disadvantages.

How can I design an effective inventory business product structure for my business?

Consider product relationships, usage patterns, and business objectives, and follow best practices for structure design.