When it comes to small business inventory buying, it’s a delicate dance between stocking up for success and avoiding the pitfalls of overstocking. In this guide, we’ll take you on a wild ride through the world of inventory management, with tips, tricks, and enough humor to keep you entertained along the way.

Get ready to navigate the treacherous waters of forecasting demand, optimizing levels, and negotiating with suppliers like a pro. We’ll show you how to avoid the dreaded inventory shrinkage and embrace the power of technology to streamline your operations. So, buckle up and let’s dive into the thrilling world of small business inventory buying!

Inventory Management Techniques

Inventory management is crucial for small businesses, as it helps streamline operations, reduce costs, and improve customer satisfaction. By effectively managing inventory levels, businesses can ensure they have the right products in stock to meet customer demand while minimizing waste and spoilage.

Inventory Management Systems

There are various inventory management systems available, including:

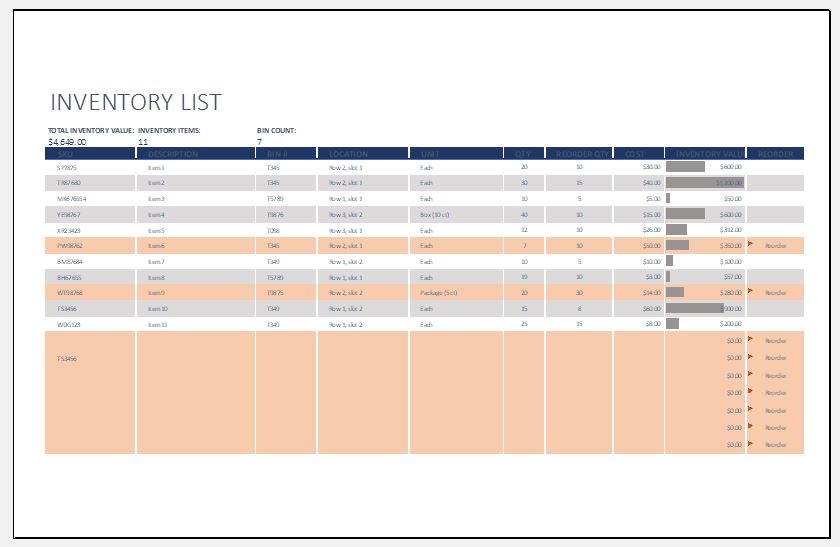

- Manual systems:Involve manual tracking of inventory levels using spreadsheets or physical records.

- Automated systems:Use software to track inventory levels, generate reports, and optimize stock levels.

- Cloud-based systems:Offer real-time inventory visibility and can be accessed from anywhere with an internet connection.

Importance of Tracking Inventory Levels

Tracking inventory levels is essential for several reasons:

- Prevents stockouts:Businesses can monitor inventory levels to avoid running out of popular products, which can lead to lost sales and customer dissatisfaction.

- Reduces overstocking:By tracking inventory levels, businesses can avoid overstocking, which can result in increased storage costs, product damage, and obsolete stock.

- Improves cash flow:Effective inventory management helps businesses optimize stock levels, reducing the amount of capital tied up in inventory and improving cash flow.

Purchasing Strategies

Let’s dive into the art of inventory buying, where we’ll negotiate like master Jedi and master the bulk purchasing game. We’ll also explore the secret behind lead times that can make or break your inventory game.

Negotiating with Suppliers, Small business inventory buying

Negotiation is a dance, a delicate tango between you and your suppliers. Here are some slick moves to sway them in your favor:

- Research, my padawan:Know your stuff before you step into the negotiation ring. Research your suppliers, their products, and industry trends. Knowledge is power, and power wins discounts.

- Build relationships:Suppliers aren’t just faceless corporations; they’re people too! Build rapport, show appreciation, and go the extra mile to nurture those relationships. Trust me, it’ll pay off in the long run.

- Be flexible:Don’t be afraid to compromise. Sometimes, it’s better to get a slightly higher price on a reliable product than a bargain on a flaky one. Flexibility is the key to unlocking the best deals.

- Don’t be afraid to walk away:If the negotiation isn’t going your way, don’t be afraid to walk away. There are plenty of other suppliers out there, and you don’t want to settle for anything less than a win-win situation.

Bulk Purchasing: The Art of Hoarding

Bulk purchasing is like a treasure hunt where you get to hoard inventory like a dragon guarding its gold. Here’s why it rocks:

- Discounts, galore:Suppliers love when you buy in bulk. It saves them time and effort, and they’re usually willing to pass on the savings to you in the form of sweet discounts.

- Reduced shipping costs:When you buy a lot of stuff at once, you can often negotiate lower shipping costs. Plus, you’ll only have to deal with one shipment instead of multiple, saving you time and hassle.

- Consistency:Bulk purchasing ensures you have a consistent supply of inventory. No more worrying about running out of stock at the worst possible moment.

- It’s just plain fun:There’s something satisfying about having a warehouse full of inventory. It’s like being a modern-day Scrooge McDuck, swimming in a sea of goods.

Lead Times: The Time Traveler’s Guide to Inventory

Lead times are like the secret ingredient in the inventory management stew. They tell you how long it will take for your order to arrive. Understanding lead times is crucial for keeping your inventory levels in check:

- Plan ahead:Knowing the lead time allows you to plan your inventory purchases accordingly. You don’t want to be caught with your pants down (or, in this case, with empty shelves).

- Avoid overstocking:If you know your order will take a while to arrive, you can avoid overstocking by ordering smaller quantities more frequently.

- Keep your customers happy:Accurate lead times help you set realistic expectations with your customers. No one likes waiting forever for their stuff, so transparency is key.

- Predict the future:Lead times can help you predict future demand. If you see a spike in orders, you can adjust your purchasing plans to avoid stockouts.

Forecasting Demand

Predicting what your customers will want and when they’ll want it is like playing a game of “Pin the Tail on the Donkey.” But with a little bit of data and a dash of intuition, you can get pretty darn close.

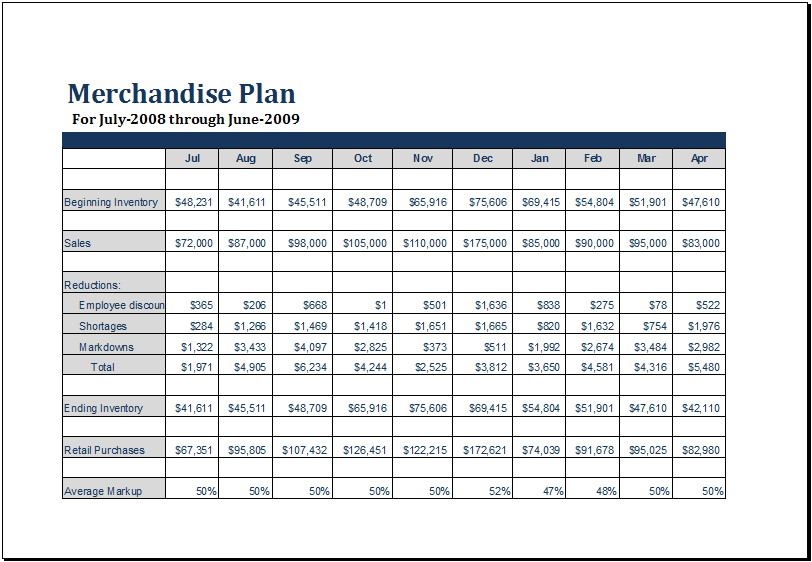

There are a few different ways to forecast demand. One way is to look at historical data. What did you sell last year? Last month? Last week?

By tracking your sales patterns, you can start to see trends that can help you predict future demand.

Seasonality

Another thing to consider is seasonality. Do you sell more ice cream in the summer? More snow shovels in the winter? By understanding how your sales fluctuate throughout the year, you can make sure you have enough inventory on hand to meet demand.

Data Analysis

Finally, don’t forget about data analysis. There are a number of software programs that can help you analyze your sales data and make more accurate demand forecasts. These programs can help you identify trends, spot patterns, and make predictions about future demand.

Inventory Optimization

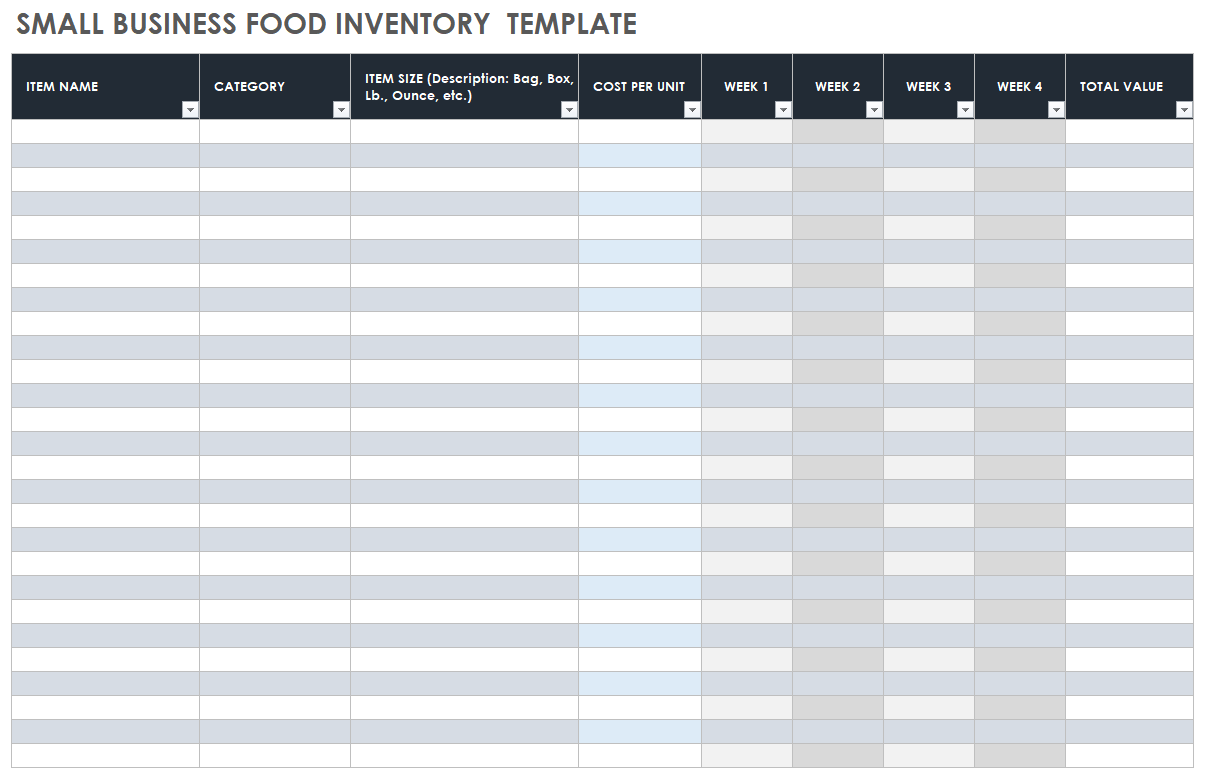

Inventory optimization is the process of finding the right balance between holding too much and too little inventory. The goal is to minimize the total cost of inventory, which includes the cost of holding inventory, the cost of ordering inventory, and the cost of stockouts.

There are a number of techniques that can be used to optimize inventory levels. One common technique is the ABC analysis. This technique divides inventory into three categories: A, B, and C. A items are the most important items, and they should be closely managed.

B items are less important than A items, but they are still important enough to be managed closely. C items are the least important items, and they can be managed less closely.

Another common technique for optimizing inventory levels is the safety stock. Safety stock is a buffer of inventory that is held to protect against stockouts. The amount of safety stock that is needed depends on a number of factors, including the demand for the item, the lead time for the item, and the cost of a stockout.

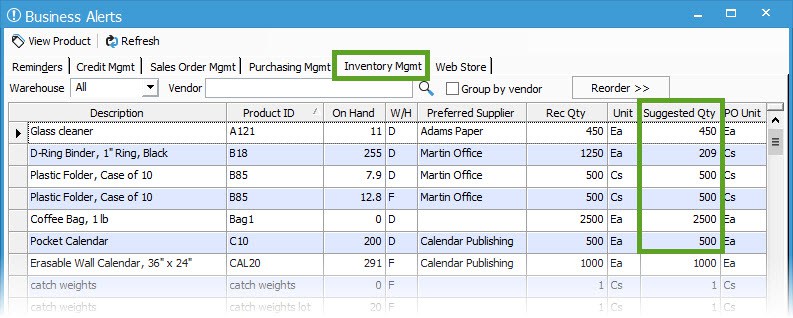

Technology can also be used to help optimize inventory levels. There are a number of software programs that can help businesses track inventory levels, forecast demand, and place orders. These programs can help businesses to reduce the cost of inventory and improve customer service.

Techniques for Optimizing Inventory Levels

- ABC analysis

- Safety stock

- Technology

Concept of Safety Stock

Safety stock is a buffer of inventory that is held to protect against stockouts. The amount of safety stock that is needed depends on a number of factors, including the demand for the item, the lead time for the item, and the cost of a stockout.

“Safety stock is like a rainy day fund for your inventory.”

Use of Technology in Inventory Optimization

Technology can be used to help optimize inventory levels in a number of ways. Some of the most common uses of technology in inventory optimization include:

- Tracking inventory levels

- Forecasting demand

- Placing orders

Cost Control

In the realm of small business inventory, where every penny counts, cost control is the watchword of the wise. Let’s dive into the treasure chest of strategies to keep those inventory costs at bay!

Inventory Shrinkage: The Silent Thief

Inventory shrinkage is like a stealthy ninja, pilfering your profits while you’re none the wiser. It can stem from theft, damage, or plain old counting errors. Embrace vigilance and implement robust security measures to thwart this sneaky adversary.

Inventory Valuation Methods: A Tale of Two Tales

Inventory valuation methods are the magical tools that transform your inventory into cold, hard cash on paper. Each method has its own quirks and charms. FIFO (First-In, First-Out) assumes your oldest inventory items are sold first, while LIFO (Last-In, First-Out) believes the opposite.

Weighted Average Costing, like a wise old owl, takes a blended approach, averaging the cost of all inventory items. Choose wisely, for your profits hang in the balance!

Ultimate Conclusion

![]()

Now that you’re armed with the knowledge to conquer small business inventory buying, go forth and conquer! Remember, it’s not just about the numbers; it’s about finding the sweet spot where efficiency meets profitability. And hey, if you make a few mistakes along the way, don’t worry – they’re just opportunities to laugh it off and learn from your misadventures.

Happy inventorying!

Q&A: Small Business Inventory Buying

Q: What’s the secret to negotiating with suppliers like a boss?

A: Charm, wit, and a willingness to walk away if the deal isn’t right. Plus, a few tricks up your sleeve, like comparing prices and playing suppliers against each other.

Q: How do I forecast demand without a crystal ball?

A: Embrace the power of data! Analyze historical sales, keep an eye on trends, and don’t be afraid to ask your customers what they want. A little bit of research can go a long way.

Q: What’s the best way to optimize inventory levels?

A: It’s all about finding the balance between having enough stock to meet demand and not tying up too much cash in inventory. Safety stock is your friend, but don’t overdo it. And remember, technology can be your secret weapon for tracking levels and making smart decisions.